適應新能源領域的需求:隨著新能源汽車、智能電網、光伏設備等新興行業的發展,匯流排的應用可能會更加廣泛。例如,匯流排在充電樁、配電櫃、換電設備等領域的使用有望進一步增加,因其具有傳輸效率高、安全穩定、占地面積小等優點。Adapting to the demands of the new energy field: With the development of emerging industries such as new energy vehicles, smart grids, and photovoltaic equipment, the application of busbars is likely to become more widespread. For instance, the use of busbars in areas such as charging piles, power distribution cabinets, and battery swapping equipment is expected to increase further because of their advantages such as high transmission efficiency, safety and stability, and small floor space.

提高穩定性和可靠性:電力系統對穩定性和可靠性的要求日益提高,匯流排會採用更可靠的傳輸技術和設備,例如增加更多的安全保護裝置和功能,以確保電力傳輸的穩定可靠。Improving stability and reliability: The requirements for stability and reliability in the power system are increasing day by day. Busbars will adopt more reliable transmission technologies and equipment, such as adding more safety protection devices and functions to ensure the stability and reliability of power transmission.

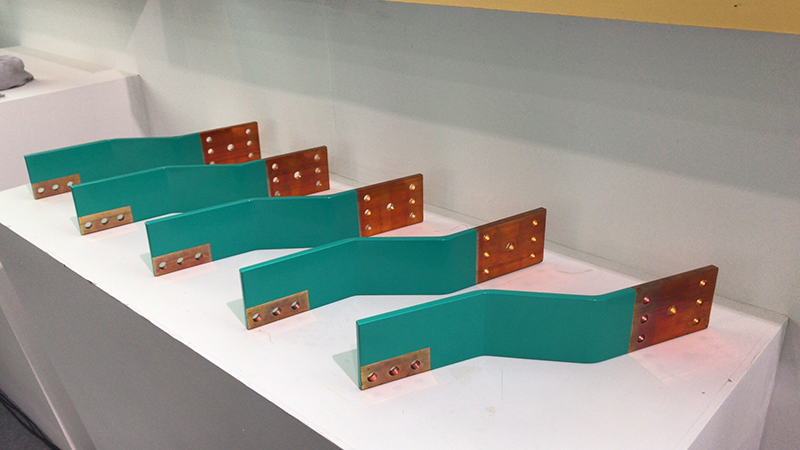

定制化產品增加:定制化銅匯流排的形狀及截面積可根據客戶需求進行調整,能更好地滿足多樣化的應用需求,未來其市場占比有望提升。Increasing customized products: The shape and cross-sectional area of customized copper busbars can be adjusted according to customer demands, which can better meet diverse application requirements. The market share of such products is expected to increase in the future.

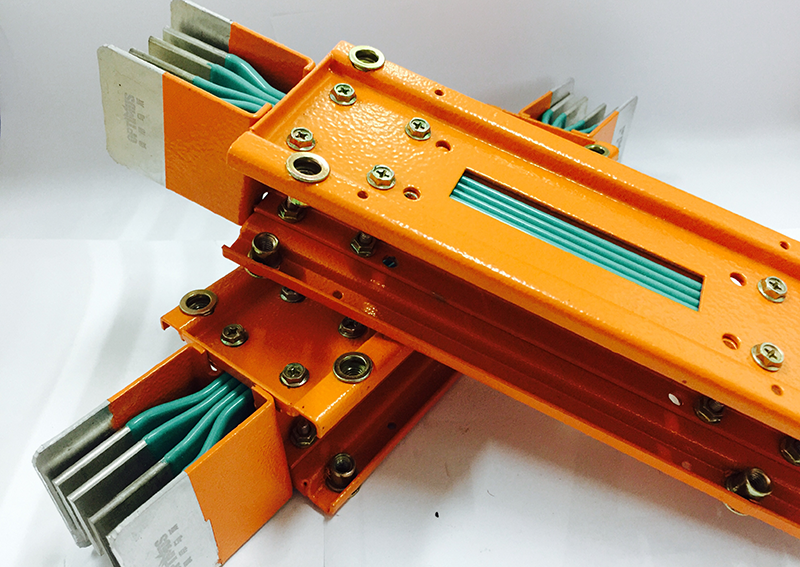

注重環保設計:由於人們環保意識的增強,匯流排將更注重環保性設計,採用環保材料和設備,減少對環境的影響。眾孚生產的環氧樹脂流化匯流排擁有良好的絕緣性能,這項絕緣技術通過環保部門的嚴格審查,高溫傳導與短耐能力使得損耗減少並節省電費支出,全部自動化PLC控制,表面處理極為光滑、均勻、美觀!溫度影響導體阻力,而環氧樹脂的電阻小,散熱好,可以減少用電,以此達到節能。流化高效自動生產線、流化前處理均以物理作業執行、流化層可以重複迴圈使用、相同電流負載,導體尺寸可以變小、降低銅礦的開採需求。具有節能環保的效益。Emphasizing environmental protection design: Due to the enhanced environmental awareness of people, busbars will pay more attention to environmentally friendly designs, adopt environmentally friendly materials and equipment, and reduce the impact on the environment. The epoxy resin fluidized bus duct produced by Optimus has excellent insulation performance. This insulation technology has passed the strict review of the environmental protection department. The high-temperature conduction and short-term withstand capacity reduce losses and save electricity expenses. It is fully automated PLC controlled, and the surface treatment is extremely smooth, uniform, and beautiful! Temperature affects the resistance of the conductor, and the resistance of epoxy resin is small and the heat dissipation is good, which can reduce electricity consumption and achieve energy saving. The fluidized high-efficiency automatic production line, the fluidized pre-treatment are all carried out by physical operations, the fluidized layer can be recycled, for the same current load, the conductor size can be reduced, and the demand for copper mining can be reduced. It has the benefits of energy conservation and environmental protection.

未來,隨著新技術的應用和材料的不斷創新,匯流排將更好地適應工業和商業領域的需求,並以更高的效率和可靠性為電力傳輸注入新的動力。In the future, with the application of new technologies and continuous innovation of materials, bus ducts will better adapt to the demands of the industrial and commercial fields and inject new impetus into power transmission with higher efficiency and reliability.